INTEGRATED POWER & CONTROL PROVIDER INC.

INTEGRATED POWER & CONTROL PROVIDER INC.

We are envisioned to be a Total Solutions Provider to you our valued customer in the industrial, marine, power generation and various industry..

Contact us

Centralized

VM600

VM600 system can provide integrated turbo machinery

protection, condition and advanced performance

monitoring in a single 6U high 19 inch rack. It is a

digital, modular and scalable hardware and software

solution for plant usage optimization from a single

advanced, flexible system. Each VM600 system can be

easily configured to meet the specific needs of each

application with transducer inputs from accelerometers,

dynamic pressure sensors, proximity probes, and

velocity, temperature and air gap sensors. These inputs

are analyzed to monitor shaft vibration (relative and

absolute), displacement, eccentricity, oil pressure,

absolute vibration, speed, expansion (absolute,

differential and casing) and combustion dynamic

pressure. VM600 is SIL 1 rated.

Distributed

VibroSmart

Our next generation distributed monitoring solution

offers the same rock-solid safety assurance as our

centralized solution, but with ATEX Zone 2 (Class I

Division 2) certified modules that can be mounted

directly on machinery. This simplifies installation and

reduces the need for low-noise cabling, resulting in

savings of up to 30%. The VibroSmart system of modular

and scalable products is highly flexible. It supports

all sensor types and uses real-time Ethernet technology

to communicate and deliver API-standard machinery

monitoring functions.

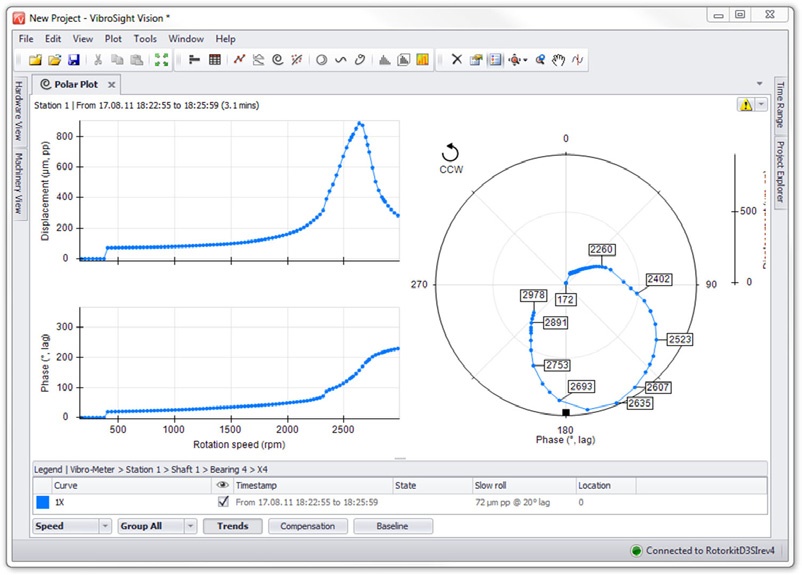

Visualized

VibroSight

The software platform through which data from both

platforms are visualized, trended and analyzed. Sensor

data is fed through VM600 and VibroSmart's advanced

monitoring and diagnostic functions, enabling informed

decisions on all aspects of power plant management. Its

open architecture makes it easy to expand the system and

integrate additional data with existing monitoring

functions.

SENSOR SYSTEMS

After decades working with the world's turbine manufacturers and power plant integrators, Meggitt has developed one of the widest ranges of active sensors for extreme environments. Today, we monitor virtually every parameter with the extreme environment sensors necessary to provide detailed information on equipment condition.

With field-proven MTBFs as high as one million hours,

they are the foundation on which to integrate the

advanced diagnostic tools that help users with the

prognostics needed to turn data into explicit

maintenance actions and monitoring into active

management

of system condition.

Accelerometers

Meggitt offers a variety of high reliability accelerometers through our well known Vibro-Meter, Endevco and Wilcoxon Research product lines, all with industry leading MTBFs that are typically several times greater than competitors' products. Some accelerometers, such as the Vibro-Meter CA series, operate in the charge mode and work in the most severe and highest temperature environments, while others, such as the CE sensor series, include integrated electronics and are hence more economical and simpler to integrate.

Meggitt offers a wide range of sensors with options to

suit every application

● sensitivities from 10

to 100 pC/g and 10 to 500 mV/g

● maximum operating

temperatures from 120 deg. to 700 deg. C

● frequency ranges as

low as 0.05 or as high as 20,000 Hz

● explosion proof

certification

Pressure sensors

Dynamic pressure monitoring is key to optimizing NOX

emissions while maintaining ideal fuel efficiency.

Meggitt's dynamic pressure sensors, the CP series from

the Vibro-Meter line and the 522 series from the Endevco

line, are qualified by most major gas turbine

manufacturers for combustor pulsation monitoring and

offer the highest reliability in the extreme temperature

of modern gas turbine combustors. The GaPO4 (gallium

phosphate) piezoelectric material used ensures

outstanding thermal behavior (no pyroelectricity) and

virtually constant sensitivity. Our acceleration

compensated patented technology has

● the highest sensitivity in

the industry, over 750 pC/bar

● extreme temperature

capability with continuous operation up to 777 deg.C

● high overload capability, up

to 350 bar

● explosion proof

certification

Meggitt's dynamic pressure sensors lead the industry in

combustion monitoring and, in conjunction with the VM600

system, provide a complete retrofit combustion

monitoring system.

Proximity transducers

Meggitt's Vibro-Meter TQ series eddy current

transducers make contact less measurements in gas

turbines and turbo-compressors, including shaft

relativevibration, radial or axial displacement,

differential expansion, thrust and eccentricity. We

offer a wide variety of performances to meet any

need and Meggitt can provide direct drop-in

replacements for most any proximity transducer

currently in the field.

●

voltage and

current transmission (for long distances)

● -40

deg to 180 deg. C

● a variety of

measurement ranges, from 2 to 22 mm

● explosion proof

certification and API 670 compliance